A Timely Report by IDC on Sustainable Data Storage Strategies

If 2020 will be remembered for the global COVID pandemic, 2021 will hopefully be remembered as the year global warming and climate change took center stage. This year has certainly had more than its fair share of climate change-related natural disasters from extreme weather caused by a warming of the polar regions, to raging forest fires, to flooding across the globe. Consumers, governments, and organizations are taking notice and action. Carbon reduction pledges are being made as sustainability is now a strategic imperative for business leaders across all industries.

The Energy Intensive IT Industry

The IT industry is not exempt from sustainability mandates. The IT industry is said to consume 2% to 3% of the world’s electrical supply and this number is expected to rise in the years ahead amidst the rapid expansion of digital transformation and exponential data growth. Data centers are major consumers of energy and are looking for ways to become more sustainable.

The Need for Energy Conservation

A new IDC whitepaper, sponsored by Fujifilm, entitled “Accelerating Green Datacenter Progress with Sustainable Storage Strategies” provides an in-depth analysis of the significant energy savings and resulting CO2 emissions reduction that can be achieved by moving more data from energy-intensive storage mediums like hard disk drive arrays to environmentally friendly tape storage.

For data center operators, much focus has been placed on renewable sources of energy but renewables can’t come online fast enough or cheaply enough to keep up with digital transformation and the rapid growth of data. Therefore, energy conservation must also be the focus of every large data center operator.

Storing Zettabytes of Cold Data

The IDC report shows that data to be stored has grown from 2.0 zettabytes (ZB) in 2016 to 4.1 ZB in 2020 and is expected to reach 11.1 ZB in 2025. Just one ZB is a vast amount of data equal to one million petabytes that would need 55 million 18 TB hard drives or 55 million 18 TB LTO-9 tapes to store.

An interesting fact about data is that it quickly goes cold and access frequency drops off significantly after just 30, 60 or even 90 days. In fact, industry analysts project that 60% to 80% of all data stored is cold and qualifies as “archival.” Yet through inertia, that data often remains on energy-intensive, constantly spinning and heat-producing tiers of storage like hard disk drives. Tape does not consume any power unless being read or written to by a tape drive. As such, tape supports green data center initiatives with its ability to store data near-line in an active archive or offline without consuming power, and thereby reducing CO2 emissions.

Reducing CO2 Emissions with Tape

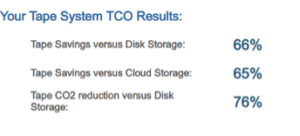

The IDC paper shows that in a certain scenario if more of the world’s data is appropriately designated as archival and migrated to tape, a 43.7% reduction in CO2 can be achieved over the forecast period. This equates to an avoidance of 664 million metric tons of CO2 (equal to CO2 produced by 144 million passenger vehicles in one year or 80 million homes in one year).

Company leaders should indeed evaluate all IT resources through a lens of sustainability. Doing so will uncover the environmental benefits of shifting more data to today’s modern and highly advanced tape storage.

For the complete details, you can access the full IDC report here.

LTO tape is an ideal solution for M&E companies. LTO is an open format designed for interoperability and together with LTFS, provides easy data access and management—perfect for easy file share, high performance, and improved workflow.

LTO tape is an ideal solution for M&E companies. LTO is an open format designed for interoperability and together with LTFS, provides easy data access and management—perfect for easy file share, high performance, and improved workflow.