Cutting-Edge Data Storage Solutions from XenData Include LTO Data Tape

Executive Q & A with Dr. Phil Storey, CEO of XenData

Q1: Welcome Phil to this Fujifilm Insights Blog Executive Q & A! Please tell us a bit about XenData and your role and responsibility as CEO.

Ans: Thank you Rich. I and our CTO, Mark Broadbent started XenData over 20 years ago and our product concept has not really changed in that time.

We wanted to develop software to manage tape libraries and RAID for long term secure storage of files and to combine the best characteristics of each. That is disk access times combined with the speed, security and longevity of tape.

The other thing that we wanted was a different business approach. Remember that we started XenData just after the dot com era when there were a huge number of risky businesses that started and then failed. We wanted a solid business with reliable products and great support – which I think we have.

Q2: XenData has been a long-time sponsor of the Active Archive Alliance and you continue to innovate in the area of active archiving. Can you tell us about your LTO Archive Appliances?

Ans: I mentioned that our business concept was to develop software. Well, we learned along the way that customers want solutions that are as turnkey as possible. So today, we mainly sell archive appliances managed by XenData software. By supplying the combined hardware and software, we are able to guarantee performance and minimize any possible problems that come with unbounded hardware options.

Our LTO archive appliances manage one or more LTO libraries and include managed RAID, from a few TB to a PB of disk. We support almost all tape libraries, including from Dell, HPE, IBM, Spectra, Quantum and Qualstar. Our appliances make writing to LTO just like writing to disk on a network. We also have a private cloud interface. We can replicate to public cloud, etc. I could go on. But in summary, by combining disk, tape and cloud we do provide strategic active archive options for our customers.

Q3: So it seems LTO tape still has a lot to offer, what are the key features and benefits appreciated by your customer base?

Ans: In summary, I would say, LTO supports high performance active archiving at a reasonable cost. Most of our customers have at least several 100s TB. It is at that volume of data and above where LTO is particularly attractive from a cost perspective. Of course, the fundamentals of tape are a must for our customers which are high reliability and long life. And in these times of climate change, the low energy profile and low carbon footprint of tape is attractive too.

I should add that we have over 1,500 installations with LTO libraries and about 90% of these are for Media & Entertainment type applications. Our customers include TV stations, Hollywood studios, video production and post-production companies as well as many marketing departments for large corporations and governmental organizations.

Q4: You mentioned Media & Entertainment customers and their appreciation of your LTO tape solutions, tell us about your new Media Portal software?

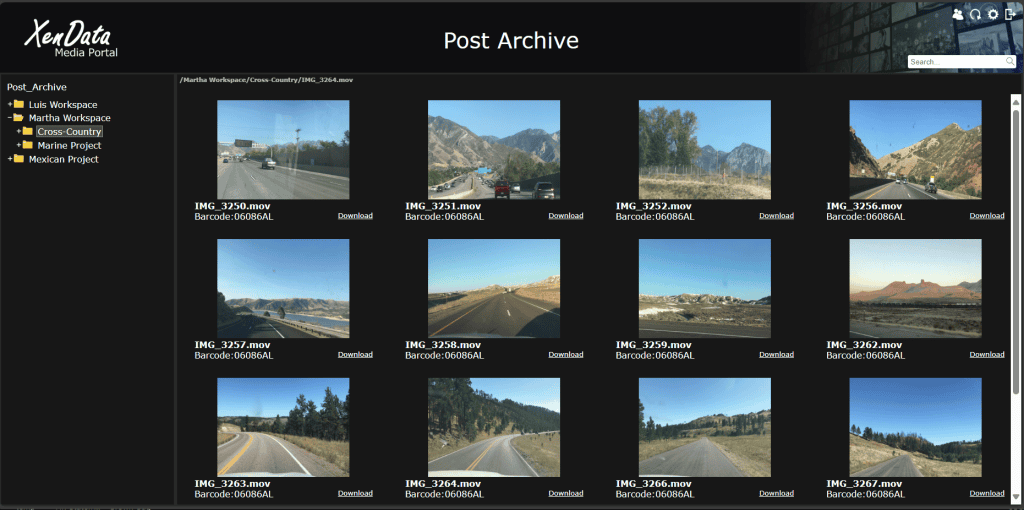

Ans: This is yet another innovative interface into our LTO archive systems. We have our core file-folder interface that can be accessed via standard windows network protocols like SMB and NFS, an option for a private cloud interface that makes accessing the archive like writing to and reading from Amazon Web Services S3 and now Media Portal adds a web interface. A user can browse the file-folder structure of their archive, see previews of video files and image files and then download the files that they need. We also have a search capability which is based on file and folder name. Media Portal will be released later this year and I am very excited about it, especially as it opens up all sorts of options for future development including AI options like converting speech to text and then searching on the text.

Q5: You mentioned that most of your archive installations are for Media & Entertainment applications. Would you tell us more about some of the other application areas?

Ans: We have installations in video surveillance, healthcare and life sciences applications. A solution that combines both disk and LTO tape is particularly attractive for large video surveillance installations because it offers longer retention periods with massive scalability at a very reasonable cost.

Q6: You recently returned from the IBC show in Amsterdam in mid-September. What can you share about the show; what was the buzz overall and in storage specifically?

Ans: Not surprisingly, AI was a key theme at the show, with a dedicated AI Tech Zone. The show also addressed sustainability, including energy efficiency in devices and delivery systems. So for us, it was super busy as there is lots of demand for long-term energy efficient storage. One of the recurring themes was the realization among our customers and prospective customers that cloud is so expensive for users even with just a few hundred TBs of content.

Q7: Finally, when you are not globe-trotting and running XenData, what do you like to do in your spare time?

Ans: Last year, my wife and I moved from California to just outside of Minneapolis to be close to our two lovely granddaughters. As you know, the winters are brutal in Minnesota, but we had a plan for that. Three years ago, we started designing and building a house on the beach in the Yucatan, just north of Merida. We only completed the project in July of this year. So, the answer to your question, ‘what do we do now’ is just one word: relax!

Thanks for your time Phil, and we wish you a lot of success with your innovative LTO tape solutions!

As both an active archive and tape evangelist, I’m excited to share how

As both an active archive and tape evangelist, I’m excited to share how

Big data, artificial intelligence, machine learning, video surveillance, and social media are among some of the biggest trends in the technology industry driving the creation of massive data sets that need to be managed and retained.

Big data, artificial intelligence, machine learning, video surveillance, and social media are among some of the biggest trends in the technology industry driving the creation of massive data sets that need to be managed and retained. In response to this challenge, the tape ecosystem has significantly expanded its capabilities in recent years. LTO tape capacity continues to increase as new magnetic particles like Barium Ferrite and Strontium Ferrite will help to scale tape areal density for decades to come and current roadmaps signal that the trend of steady tape innovation will continue well into the future. It’s time to rethink existing data storage practices and take advantage of advanced magnetic tape for delivering the most sustainable, cost effective, highly scalable, and reliable mass storage systems.

In response to this challenge, the tape ecosystem has significantly expanded its capabilities in recent years. LTO tape capacity continues to increase as new magnetic particles like Barium Ferrite and Strontium Ferrite will help to scale tape areal density for decades to come and current roadmaps signal that the trend of steady tape innovation will continue well into the future. It’s time to rethink existing data storage practices and take advantage of advanced magnetic tape for delivering the most sustainable, cost effective, highly scalable, and reliable mass storage systems. Video surveillance has become an essential tool in many industries, from law enforcement to retail, transportation, and critical infrastructure. The ability to capture and analyze video footage has enabled organizations to enhance their security, prevent crimes, optimize operations, and make data-driven decisions.

Video surveillance has become an essential tool in many industries, from law enforcement to retail, transportation, and critical infrastructure. The ability to capture and analyze video footage has enabled organizations to enhance their security, prevent crimes, optimize operations, and make data-driven decisions. Recently I had the opportunity to meet with a newly appointed Chief Sustainability Officer (CSO) at a major scientific research organization. In this new position that seems to be trending across many industries, this CSO has been tasked with the overall responsibility for understanding the organization’s energy profile and how its carbon footprint is spread across its many different departments and then to figure out what actions can be taken to help achieve its carbon reduction goals. With this understanding in place, the CSO will proceed to put downward pressure on the department heads to make meaningful change.

Recently I had the opportunity to meet with a newly appointed Chief Sustainability Officer (CSO) at a major scientific research organization. In this new position that seems to be trending across many industries, this CSO has been tasked with the overall responsibility for understanding the organization’s energy profile and how its carbon footprint is spread across its many different departments and then to figure out what actions can be taken to help achieve its carbon reduction goals. With this understanding in place, the CSO will proceed to put downward pressure on the department heads to make meaningful change. The National Association of Broadcasters (NAB) held their annual conference this week in Las Vegas. Some 68,000 attendees from broadcasters to screenwriters, advertisers and streamers, to producers and filmmakers were eager to learn about the latest in media and entertainment technology. Some 1,200 exhibitors set up shop in the Las Vegas convention center, including FUJIFILM with our FUJINON lenses, and Recording Media in the form of LTO tape technology.

The National Association of Broadcasters (NAB) held their annual conference this week in Las Vegas. Some 68,000 attendees from broadcasters to screenwriters, advertisers and streamers, to producers and filmmakers were eager to learn about the latest in media and entertainment technology. Some 1,200 exhibitors set up shop in the Las Vegas convention center, including FUJIFILM with our FUJINON lenses, and Recording Media in the form of LTO tape technology. I attended the International Security Conference West (ISC West) in Las Vegas last week. The show was well attended with some 20,000 visitors packing the aisles and mobbing the booths of some 650 vendors. The show covers everything from video surveillance to computer and communications security, to physical plant security, loss prevention, and more.

I attended the International Security Conference West (ISC West) in Las Vegas last week. The show was well attended with some 20,000 visitors packing the aisles and mobbing the booths of some 650 vendors. The show covers everything from video surveillance to computer and communications security, to physical plant security, loss prevention, and more.