Spotlighting Active Archive with Solutions from SAVARTUS

Executive Q & A with Rick Bump, CEO of SAVARTUS

Q1: Welcome Rick to this Fujifilm Insights Blog Executive Q & A! Please tell us a bit about SAVARTUS and your current role as CEO.

Ans: I co-founded SAVARTUS with Christopher Rence to address the pressing challenges in data management. We recognized a growing need driven by the trajectory of data and its evolving demands—challenges the status quo simply can’t handle. SAVARTUS delivers storage solutions, blending innovative optical technology and LTO options, all accessible through our Unified Data Interface (UDI) software. We all know that data is surging—IDC estimated over 180 zettabytes globally by 2025, fueled by AI generating massive datasets and businesses digitizing operations. Costs are exploding too; traditional cloud storage or HDDs rack up steep bills, especially with egress and other API fees for AWS archival storage. Compliance pressures, like GDPR or HIPAA, demand long-term retention and secure destruction, while environmental impact is a rising concern—data centers eat up 1-2% of global electricity, clashing with sustainability goals. The old approaches—power-hungry disks, or costly cloud tiers—lag behind, failing to balance affordability, speed, and eco-friendliness That’s why Christopher and I launched SAVARTUS. Our optical active archive offers retrieval at low cost—fast and cost-effective—while using near-zero idle power. Tape keeps deep storage at the lowest total-cost-of-ownership (TCO) and our UDI software manages it all. I’m thrilled to lead us in tackling these gaps.

Q2: As you seek to provide data management solutions for organizations, from your perspective, what is driving data growth and what is challenging the status quo?

Ans: From our perspective, data growth is being propelled by a mix of technological, regulatory, and behavioral forces, all reshaping how organizations handle their information, while an evolving need to manage digital assets from creation through intentional destruction adds further complexity. First, digital transformation is a primary driver. Businesses are digitizing operations—supply chains, customer interactions, and more—producing vast structured and unstructured data. IoT devices in manufacturing or healthcare generate continuous sensor streams, and AI workloads, especially generative models, create massive datasets for training and content production. IDC’s forecast of over 180 zettabytes by 2025 is proving conservative as these technologies scale. Second, regulatory and compliance demands are extending data lifecycles. Frameworks like GDPR, HIPAA, and SEC Rule 17a-4 require retention—sometimes decades-long—pushing organizations to archive data cost-effectively and securely. This ties directly to the need for end-to-end digital asset management: data must be tracked from creation (for example, for patient records or financial transactions), preserved for legal holds, and eventually destroyed intentionally to comply with privacy laws or reduce liability. A healthcare provider, for instance, might retain records indefinitely but must ensure secure deletion when permissible, amplifying storage demands. Third, user behavior is exploding data volume. Remote work has surged cloud collaboration data—emails, videos, documents—while consumers fuel petabytes through social media, streaming, and e-commerce, captured for analytics. This “datafication” creates assets that organizations must manage holistically: created by users, stored for insights, and destroyed when obsolete, not just left to pile up. What’s challenging the status quo? Traditional data management—HDDs and online cloud—are faltering under these pressures when it comes to long term archival storage for large capacities. Cost is the disruptor: AWS Deep Archive offers $0.00099/GB/month, but retrieval fees and 12- 48-hour latency frustrate users needing quick access. HDDs consume power and hit scalability walls as data centers face energy and environmental constraints. Security is shaking things up too. Ransomware, up 13% in 2024 per Verizon’s DBIR, exploits online storage, driving demand for offline, air-gapped solutions. The old “store everything online” model is crumbling as breaches expose vulnerabilities, especially when compliance demands auditable, immutable records from creation to destruction—records that must be both secure and securely disposed of on schedule. A critical challenge is the need to access traditionally archived data for AI, ML, or other business requirements driving active archive capabilities. The status quo treated archives as static vaults— data locked away on tape or deep cloud tiers, retrieved only for audits. Now, organizations want to mine historical data for training AI models, running analytics, or feeding real-time applications. A media company might pull decades-old footage to train a content recommendation engine, or a retailer might analyze archived transactions for predictive trends. Multi-hour retrieval-SLA’s and cloud’s retrieval costs clash with these active use cases, demanding faster, more accessible archiving. Sustainability is another disruptor. Data centers, consuming 1-2% of global electricity, face ESG scrutiny. HDDs’ constant energy draw does not cut it, while our optical discs—near-zero idle power, 50–100-year lifespan—offer a greener alternative. In essence, data growth stems from digitization, regulation, and behavior, intensified by the need to manage assets from creation to destruction. The status quo is challenged by cost inefficiencies, security risks, sustainability pressures, and the shift to active archiving for AI and ML. For example, our Archive-as-a-Service solution offering (AaaS), with 2–5-minute retrieval, offline security, and low-energy optical storage, addresses these drivers and disruptions, enabling organizations to handle data’s full lifecycle smarter and faster.

Q3: You mentioned that SAVARTUS delivers storage solutions based on optical and tape technologies. Can you elaborate on the ideal scenario for each of those diverse solutions?

Ans: At SAVARTUS, we leverage optical and tape technologies to provide tailored storage solutions, each excelling in distinct scenarios, complemented by our software for unified data access. These offerings address the diverse needs of organizations managing explosive data growth, from creation to destruction, while tackling challenges like cost, security, and accessibility. Here’s how each technology fits into an ideal scenario. Our optical storage shines in scenarios demanding random access, robust security, and sustainable long-term retention for moderate to large data volumes. The ideal use case is an organization needing an on-premise active archive—data that’s not accessed daily but requires quick availability for operational or analytical purposes, such as AI/ML training, compliance audits, or historical analysis. Imagine a media company managing decades of video assets. They need to archive raw footage (perhaps 100 GB files) for potential reuse in new projects or AI-driven content curation. Our optical library, with retrieval times of Time-to-First-Byte in 2-5 minutes, delivers this data far faster than Cloud’s 12-hour SLA (like for AWS Deep Archive). The offline, air-gapped nature of optical discs protects against ransomware, critical for high-value digital assets, while near-zero idle power aligns with sustainability goals. Another prime scenario is regulated industries like healthcare or finance, where data must be retained for 7-10+ years, accessed occasionally for audits, and destroyed securely per GDPR or HIPAA. Our Data Lifecycle Management (DLM) software components enhance this by managing the lifecycle – encrypting data on write, tracking retention periods, and ensuring compliant deletion. With features like customer-managed keys and WORM compliance, we justify a $0.004/GB/month premium over Deep Archive ($0.00099), offering enterprise-grade security and speed at a fraction of Veritas’s $5-$15/GB/month. Tape storage, a stalwart in our portfolio, is ideal for deep, cold storage—massive datasets retained for compliance or disaster recovery with minimal access needs. The perfect scenario is a large enterprise or government agency archiving petabytes of historical data (examples include tax records, seismic surveys) that’s rarely touched but must be preserved indefinitely at the lowest possible cost. Consider a financial institution mandated to keep transactional data for decades. Tape’s ultra-low cost—comparable to Deep Archive’s $0.00099/GB/month—makes it unbeatable for static, multi-PB archives. Our tape solutions, paired with DLM software modules, automate tiering from active systems to tape, ensuring data moves seamlessly from creation to long-term storage. The physical air-gap provides unmatched resilience against cyber threats, and tape’s 30+ year lifespan suits archival needs where retrieval Time-to-first-Byte (TTFB) isn’t urgent. For example, restoring a backup after a disaster fits tape’s strengths—high capacity (perhaps using LTO-9 at 18 TB/cartridge), high 400MB/s transfer rate and durability outweigh a higher TTFB. Tape also excels for organizations prioritizing sustainability and cost over speed. A research institute storing climate data might use tape to keep 50 PB at a fraction of cloud or HDD costs, with our DLM software modules cataloging metadata for eventual retrieval or destruction, ensuring compliance with grant mandates. Regarding the role of Data Lifecycle Management Software; our DLM software components tie these solutions together, managing data, as I like to say, with intention from creation through destruction. For optical, it enables encryption, key management, and fast indexing, supporting active use cases like AI-driven insights from archived data. For tape, it automates migration to deep storage, tracks retention, and schedules secure deletion, optimizing cost and compliance. This holistic approach—optical for accessibility and physical WORM, tape for cost and scale—lets organizations adapt to diverse needs. Why Both? Optical storage suits mid-tier archiving (approximately 100 TB-5 PB) with frequent-enough access, offering speed and security at $0.004/GB/month. Tape dominates ultra-large, static archives (1 PB+). Together, with our DLM software components, SAVARTUS delivers a spectrum of solutions—reasonably fast, secure (physical WORM) optical for active archives, and economical tape for deep storage and retrieval with high transfer rates—meeting the full lifecycle demands of modern data management.

Q4: Your customers can implement your solutions as cold storage, more of a traditional archive, or as an active archive. Can you explain the advantages of cold archive vs. active archive?

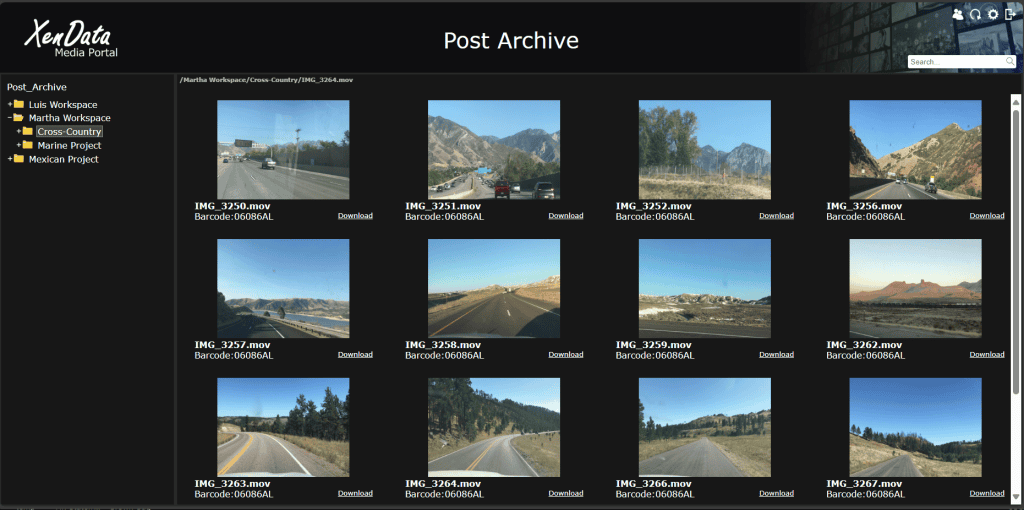

Ans: We recognize that organizations will want to use our optical and tape solutions in different ways—cold storage, traditional archiving, or an active archive. Cold archiving is what we lean on for data you stash away and rarely touch, like with our tape or the budget tier of our optical setup. It’s all about keeping costs crazy low—think tape matching AWS Deep Archive at $0.00099/GB/month. Say a government agency’s got decades of tax records to store; they don’t need them often, maybe just for an audit every few years. Cold storage is perfect here because it’s dirt cheap—tape and optical barely use power when idle—and it’s built to last, with tape good for 30+ years and our discs up to 100 years. Plus, being offline keeps it safe from hackers. Our DLM software components seal the deal by tracking retention and scheduling secure deletion, like for GDPR compliance. The trade-off? Retrieval times depend on file size and are higher for optical than with tape. Active archiving, though, is where tape- and optical have their individual advantages. Our optical solution at $0.004/GB/month really pops—is for random access type data and small files you want to grab more often. Tape on the other hand shines with its low cost and high transfer rate, making it specifically attractive for the retrieval of large files and high capacities. Both optical and tape are available with a Glacier front end, supporting on-prem and hybrid environments. With our DLM software components adding encryption on write and fast search, it’s great for things like a retailer pulling archived sales data to predict trends. The catch is it costs more than cold—$0.004 vs. $0.00099—but you’re paying for that quick access and extra utility. Basically, cold storage is your friend for cheap, long-term storage of stuff like backups or regulatory records, while active storage is the way to go if you’re actively using archived data, like for AI or quick audits. Our Unified Data Interface software keeps it all smooth, managing the whole lifecycle either way.

Q5: You mentioned AI as a driver of data storage demand, how does active archive support AI workflows based on your product solutions?

Ans: You’re right—AI is a huge driver of data storage demand these days, and our active archive solution at SAVARTUS is built to support those workflows at the backend. With AI there is a large demand for high performance data storage (HDD/Flash) for data collection, preparation, model development, training/re-training and model deployment. At the same time, after model deployment the large capacity model data must be archived for future references, retraining and for regulatory reasons. The S3/Glacier interface of our tape- and optical archive offerings is perfectly suited to work with typically object storage-based AI model front ends.

Q6: SAVARTUS recently joined the Active Archive Alliance (AAA). What benefits do you hope to enjoy as a part of AAA?

Ans: SAVARTUS’s membership in the Active Archive Alliance is a strategic move, and we anticipate several meaningful benefits from this affiliation. The Active Archive Alliance brings together a knowledgeable group of industry leaders focused on advancing active archiving, and we see this as an opportunity to strengthen our position in the storage landscape. One key benefit is the chance to network with this expert community and gain insights into the future of active archiving. With our optical solution we’re eager to collaborate with peers like IBM or PoINT Software and Systems to refine our approach. Their perspectives could help us enhance features like retrieval speed or indexing, critical for customers accessing historical data for AI-driven analytics, such as a retailer optimizing predictive models with years of sales records. Membership also elevates our influence. By engaging with the Alliance, we can contribute to shaping industry standards, showcasing how our optical technology complements tape’s established role while meeting modern demands—think fast, secure access alongside costeffective deep storage. This could resonate with enterprises, like a financial institution managing audit-ready archives. Finally, the Active Archive Alliance’s credibility enhances our reputation. Affiliation with a respected, vendor-neutral body signals trust to clients, reinforcing our DLM software component’s role in managing data lifecycles end-to-end. For a healthcare provider securing patient data, that trust could be decisive. In short, we aim to leverage expertise, influence trends, and build credibility through the Active Archive Alliance, all to advance our optical-led active archiving solutions. We’re also eyeing the credibility bump. The Active Archive Alliance is all about vendor-neutral, trusted solutions, so being part of that club signals to customers that we’re serious about solving their data growth headaches—cost, security, you name it. It’s like a stamp of approval that could sway a media company picking us over a cloud-only option for their video assets. So yes, it’s about sharpening our game, getting our name out there, and building trust—all while keeping our optical solution shining as the go-to for active archiving.

Q7: Finally, when you are not slaving away for SAVARTUS, what do you enjoy doing in your free time these days?

Ans: When I’m not working, I hunt, fish, camp, hike, scuba dive, sky dive and train our Malinois. I love being outside!

Thanks for your time, Rick, and we wish you a lot of success with SAVARTUS and in the Active Archive Alliance. Check out the SAVARTUS website at: https://savartus.com