Commitment to Sustainability at Data Center World Includes How to Avoid CO2 Emissions in Long Term Storage with Modern Data Tape Technology

I had the opportunity to present at AFCOM’s Data Center World (DCW) exhibit and conference in Austin, Texas yesterday. The first thing I have to share about this experience is how surreal it was to get back on an airplane! It was my first trip since COVID started two years ago with many zoom presentations and virtual conferences since then. But not much has changed about air travel. The seating is still cramped, the flight was packed full, and my dog gets more snacks in a four hour period than I did on my four hour flight!

Committed to Sustainability

Sustainability is a hot topic these days and was one of the main themes of this year’s DCW. It was also the topic I presented on, specifically “How to Avoid CO2 Emissions in Long Term Storage with Modern Data Tape Technology.” The good news is that the DCW attendees that I met and listened to in other sessions are genuinely concerned about the environment and worried about what kind of planet we will be leaving behind for our kids and grandchildren. They recognize the opportunity to improve sustainability in data center operations and are committed to it.

Key Questions about Storage

At the outset of my presentation, I asked for a show of hands for those directly involved in data storage. I was not surprised to confirm my suspicion that there would be few if any attendees to raise a hand, since AFCOM’s DCW is more about facilities management than storage management. But I was also glad to see this because we need everyone to be advocates for any possible sustainability improvements in IT operations. So I asked my audience to lean on their colleagues in storage and pose two simple questions to them: “If data has gone cold and is infrequently accessed, why are we keeping it on energy intensive tiers of storage like constantly spinning and heat producing HDD arrays? Why not move it to eco-friendly tape?” The attendees in my session admitted they can feel the power drain and heat being produced by endless disk arrays in their data centers.

Climate Change and Global Warming

I began my presentation by setting the stage on global warming from the forest fires in 2020, to the Texas deep freeze in early 2021, to the fact that July of 2021 was the hottest month ever on earth. Add to this the dire reports from the U.N. in late 2021 and early 2022. All this has led to changing consumer sentiment demanding that governments do more. Thankfully they are. Corporate attitudes are also changing from resistance to action on climate and we will be seeing more CSOs (Chief Sustainability Officers) being appointed and implementing change top down. Even Wall Street and the SEC are getting in on the act, demanding reporting and disclosures on corporate sustainability initiatives.

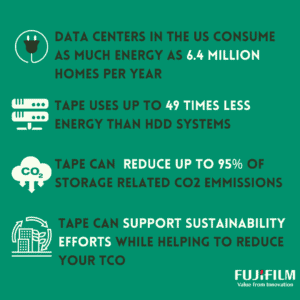

Energy Intensive IT Industry

Next, I confirmed what we all know, that the IT industry is energy intensive and its demand for energy is rapidly increasing. The demand curve for energy looks similar to the demand curve for data storage. Driven by digital transformation, IDC expects persistent data that needs to be stored to grow from 2.0 ZB in 2016 to more than 11.0 ZB in 2025, a CAGR of 27%. Suffice it to say no one in the audience really understood what a zettabyte was or that just one zettabyte was equal to the capacity of 55 million LTO-9 data cartridges or 55 million 18.0 TB HDDs. That’s a lot of storage requirement for one zettabyte, let alone 11.0 zettabytes in 2025. We are going to need a lot of flash, disk and tape to handle that kind of volume!

Renewable Energy plus Conservation

Next came the conversation about renewables and how Greenpeace has done a great job advocating for more use of renewables in data centers, especially the cloud hyperscalers. But from the looks of progress being made on this front, renewable sources of energy likely can’t come on line fast enough or cheaply enough, or in sufficient volume to satisfy the energy needs of the massive data center industry. While Fujifilm is a big fan of renewables (we use it ourselves for our LTO plant in Boston) what’s really needed is a combination of renewables and energy conservation. How about turning off those lights and HDDs before leaving the office each night!

Next came the conversation about renewables and how Greenpeace has done a great job advocating for more use of renewables in data centers, especially the cloud hyperscalers. But from the looks of progress being made on this front, renewable sources of energy likely can’t come on line fast enough or cheaply enough, or in sufficient volume to satisfy the energy needs of the massive data center industry. While Fujifilm is a big fan of renewables (we use it ourselves for our LTO plant in Boston) what’s really needed is a combination of renewables and energy conservation. How about turning off those lights and HDDs before leaving the office each night!

The Data Life Cycle

When it comes to conserving energy in data storage, one needs to understand a few simple principles related to the “data lifecycle.” Data quickly goes cold and access frequency drops off dramatically after 30, 60 or 90 days. At the same time, data retention periods are getting longer, sometimes reaching indefinite time periods. This is where data tiering saves the day as cold data can move from expensive, energy intensive tiers of storage to economy, eco-friendly tiers like modern data tape.

Advantages of Eco-Friendly Tape

I then shared the research findings from Brad Johns Consulting in his two white papers where tape consumes 87% less energy and produces 87% less CO2 than equivalent amounts of HDD storage. When analyzed over the total product lifecycle from procurement of raw materials to production to distribution to usage and finally disposal, tape produces 95% less CO2 than HDD and produces 80% less e-waste. I also shared the results of an IDC study that shows migrating more cold data from tape to HDD could result in an avoidance of 664 million metric tons of CO2 on a global basis by 2030. That’s the CO2 equivalent of 144 million automobiles being taken off the road for a full year! I also referenced research by IBM showing a side by side compare of TS4500 tape library and Bryce Canyon HDD where the IBM gear produced 80% less CO2 over a ten year period than the Bryce Canyon system. To round things out, I shared the end user perspective from an executive roundtable where Microsoft Azure stated:

“When you take the material savings and power savings, tape actually does offer quite a bit of advantage compared to other technologies that are on the market today.”

Since my audience wanted to know more, I briefly covered tape’s other benefits including:

- Tape remains the lowest cost storage media on a $/GB basis

- Tape storage supports air gap ransomware

- Tape can reliably store data for long periods with an excellent bit error rate

- Tape technology has room to grow in areal density and therefore capacity, and has a well-defined roadmap

I concluded by saying that data growth is here to stay and the volumes of valuable data are getting enormous. What the industry needs to do in support of strategic data storage management and sustainability objectives is this:

“Get the right data, in the right place, at the right time, at the right cost, and…at the right energy consumption level.”

I think the attendees got the message and now see modern tape storage as part of the carbon reduction answer for the data centers of today and tomorrow. It was well worth the snack deprived four hour flight!

We as a society, as individuals and as commercial organizations and governments need to take action. No effort is too small, even turning off a single light switch when not needed is worthwhile. Collectively we can make a difference.

We as a society, as individuals and as commercial organizations and governments need to take action. No effort is too small, even turning off a single light switch when not needed is worthwhile. Collectively we can make a difference.