It’s hard to believe, but I joined Fujifilm in the summer of 1986. Ronald Reagan was in his 2nd term as president, Jack Nicklaus, with a historic back nine at Augusta had just become the oldest winner of the Masters, and Run DMC with Aerosmith were rocking the charts with the remake of “Walk This Way”! I was hired as a Technical Service Representative for what was then the Magnetic Products Division and I got the position mostly because of my background as a broadcast television engineer. The role was to lend technical support to the professional video sales team as the target markets for the group included television stations and post production houses.

During my career at Fujifilm, I have been fortunate to have been entrusted with varied responsibilities and it has really been a case of being lucky and being in the right places at the right times. In 1988, Fujifilm started assembling VHS cassettes in Maine with a subcontractor who molded the shells and packaged the product, and I became the point person for the qualification of any VHS product assembled in the U.S. In 1990, Fujifilm announced the startup of its first coating plant in America in Greenwood, SC, that would coat VHS and DLT tape. So in 1991, I packed up my young family and moved to the Palmetto state to work at the factory as a Quality Assurance Supervisor.

In 2001, after 10 years at the Greenwood factory another opportunity presented itself as a District Sales Manager for the Pro-Video Group for the southeast region of the country; I was encouraged to apply as I had experience with the broadcast industry and was already versed in Fujifilm Pro-Video products.

So for the last 23 years, I have been fortunate to have been with the sales teams as the markets and recording media technologies have evolved. In 2005, I became a National Account Manager and in 2018, I was promoted to the role of Director of Sales, entrusted with bringing value to our customers in the Commercial enterprise channel.

Our enterprise customers face increasing storage challenges brought about by the sheer amount of valuable data being generated and the need to store this data in a way that meets the requirements for access/retrieval time, security, reliability, and budget, while also supporting their organization’s ESG goals of supporting the environment and reducing energy consumption and carbon footprint.

There is no one magic bullet to help enterprise customers address all of these storage challenges but today’s modern data tape does help address many of the issues, depending on the storage requirement. One of the key advantages of tape is that it is a proven technology and there is something to be said for that. The quantum leaps in reliability and data density have been nothing short of amazing for a technology that is now 70 years old and that not only survives but thrives. Tape has evolved to meet modern needs and on the correct storage tiers provides a robust, secure, cost-effective storage platform. Tape can also be used not only for archival/long term storage but also as a near-line solution as an active archive or for backup/DR to combat cyber crime and natural disasters.

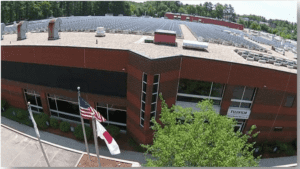

As the industry leader in magnetic tape manufacturing, Fujifilm pushes the boundaries of tape storage. A recent joint announcement between Fujifilm and IBM showed the potential capacity of 580TB cartridge using Fujifilm’s next gen Strontium Ferrite magnetic particles. Fujifilm continues to harness the power of materials with ever higher and better magnetic properties. Fujifilm is also helping companies meet their supplier goals, becoming a leading environmentally responsible supplier with packaging options that include not only recycled materials, but also a reduction in packaging components so there’s less waste and we use conscientious materials such as forest friendly certified pallets. I also have to say we are proud of the solar energy we have installed at our Bedford LTO plant.

As the industry leader in magnetic tape manufacturing, Fujifilm pushes the boundaries of tape storage. A recent joint announcement between Fujifilm and IBM showed the potential capacity of 580TB cartridge using Fujifilm’s next gen Strontium Ferrite magnetic particles. Fujifilm continues to harness the power of materials with ever higher and better magnetic properties. Fujifilm is also helping companies meet their supplier goals, becoming a leading environmentally responsible supplier with packaging options that include not only recycled materials, but also a reduction in packaging components so there’s less waste and we use conscientious materials such as forest friendly certified pallets. I also have to say we are proud of the solar energy we have installed at our Bedford LTO plant.

Having spent so much time in the industry I may be biased about the role of tape in the future of IT environments. To me, for the correct storage application including archive, active archive, backup/DR, tape offers many benefits that would make it a strategic component of a comprehensive data protection and retention plan. I always cringe when I hear a prospective customer say that tape is an old technology that is slow, expensive, and has no future. What a customer needs to realize is that the technology is not old…it is proven, it is not unreliable or fragile……there have been quantum leaps of improvement as with any technology, it is not slow……with active archive software and innovations like recommended access order, it’s a great near-line storage option. For archive/long term storage it is acknowledged to be unsurpassed; it is not expensive….in fact tape is the lowest TCO storage platform available. Tape also continues to play a role in backup/DR especially with its air gap capabilities to help fight ransomware. I could keep going, but let me just add, tape has an amazing areal density and capacity future as outlined by the LTO roadmap now stretching out to Gen 14 with more than a petabyte of compressed capacity on a single cartridge!

What is your outlook for the future of tape and the role that FUJIFILM Recording Media will play?

What is your outlook for the future of tape and the role that FUJIFILM Recording Media will play?Many of the largest IT environments currently use tape or are seriously evaluating expanding the use of tape and thus the future for the medium is bright. Fujifilm, as the world’s leading tape manufacturer will continue to play an important role in the development of tape media, drawing on its core competencies of R & D and manufacturing of thin film coatings. I believe our mission statement sums it up well: to enable organizations to effectively manage the world’s exponential data growth with innovative products and solutions, recognizing the social responsibility to protect the environment and preserve digital content for future generations.