In this executive Q&A, Shota Kamimura discusses his role at Fujifilm as a media reliability engineer, solutions to data storage problems, and the future of magnetic data tape.

I have been working at Fujifilm for more than 7 years. First, I joined the recording media research laboratory as an engineer and have been engaged in new tape media development ever since. At the research lab, I was in charge of determining system operating targets such as areal density with U.S. partner companies, designing media formulations such as magnetic particle and tape surface characteristics for example, and evaluating performances of prototype samples which were made by our manufacturing process team.

In 2021, I was transferred to FUJIFILM Recording Media USA (FRMU) as a technical sales representative. FRMU is on the cutting edge of sales and marketing as well as customer support. With my technical experience and knowledge, my current primary role is to assist U.S.-based hyperscale customers with solving technical problems, and most importantly, to reflect their unique use cases into future tape product designs. I believe this effort will be very positive for the tape storage market as so much of the world’s data is concentrated in hyperscalers.

Following tape’s environmental specs is not only a challenge for hyperscalers but also every tape customer. So, one of my biggest challenges is tape’s rigid or narrow environmental spec. In other words, tape’s allowable operational temperature and humidity ranges are more restricted than HDDs. For example, the recommended operating temperature is 25 degrees C for LTO, but regular HDD products are allowed to operate up to 60 degrees C. It turns out that this puts a burden on data center management. For example, data centers are eager to set the temperature as high as possible to reduce energy consumption related to cooling systems. In fact, some hyperscalers are working to increase the operational temperature by even just 1 degree C. Another example is that environmental deviations from the tape environmental spec due to extreme weather events such as hurricanes and seasonal humidity fluctuations can cause system down time. Therefore, the more environmentally resistant tape becomes, the more tape can contribute to hyperscale data services and sustainability goals.

First of all, given that a significant amount of data is stored in hyperscalers’ cloud services, we are aware of the necessity to make our future tape products more suitable for them, which is my goal as I mentioned earlier.

Then, tape’s current environmental spec stems from performance trade-offs. One example is wear-out. Unlike HDDs, tape systems feature contact recording, which means the tape media physically touches the tape drive head, so wear-out due to repeated recording and readback process is possible. High humidity conditions increase the friction between tape and head, so it too accelerates potential wear-out. As such it is more difficult for tape to survive high humidity condition for prolonged periods of time. Also, high friction itself can be the cause of a degradation of readback signals.

Currently the engineering team and I are working to address these trade-offs by taking advantage of Fujifilm’s core technologies. For instance, we can develop moisture resistant organic materials based on our technology to manufacture Functional Polymers, or we can make high signal-to-noise ratio tape where data can be read back even under high friction conditions by using Grain Formation Technology (new magnetic particles). The demonstration of the 580TB tape cartridge with Strontium Ferrite is proof of this concept.

In addition to the above approach, we have developed diagnostic tools to more accurately predict the performance and health level of tape systems for hyperscalers.

Tape has distinctive features compared to competitive storage systems. As the world is facing a data explosion driven by AI/ML and IoT etc., it is obvious that higher capacity and cost-effective storage systems are required. Tape stands out in long-term storage applications such as archiving and backup. Also, tape’s inherent air gap capability gives customers more confidence against cyber-attacks. Finally, I would like to emphasize the environmentally friendly aspect of tape. Tape’s energy effectiveness boils down to the reduction of CO2 emissions. Tape is estimated to cut CO2 emissions by 97% compared to HDDs over its product lifecycle. These features help customers who are growing in this data explosion era to better manage data.

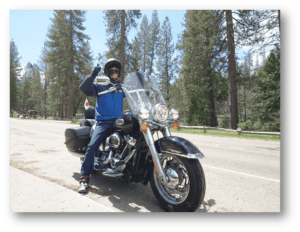

I love motorcycles. Before I moved to the U.S., I would often go on road trips in Japan on my Honda motorcycle to explore new roads, foods, and people. It always made me feel refreshed and inspired. I also enjoyed riding my motorcycle on closed-circuit racing tracks. I have stopped doing that since my relocation to the U.S., but in May of 2023, I had an opportunity to ride around on a motorcycle – a Harley Davidson – in California! It reminded me of the joy and excitement of motorcycle riding.